Finding the right band saw blade for stainless steel- Here is the guide. As you know, there are tons of options available out there, and you would like to ensure you choose the best one for your needs. Choosing the right blade for your project is vital and at SWEAT, we believe that. Here are some factors to consider before buying one.

First, check the thickness of the stainless steel that you are cutting. Less thickness means for thinner sheets you would go for a finer blade, thicker metals require the thicker blade. If the incorrectly deployed blade is going to make a bad cut, the cut won’t be a smooth one or an accurate one. It can also damage your blade or tool to the point where it is less effective or completely useless. So one of the first things we have to do is measure the thickness of the stainless steel.

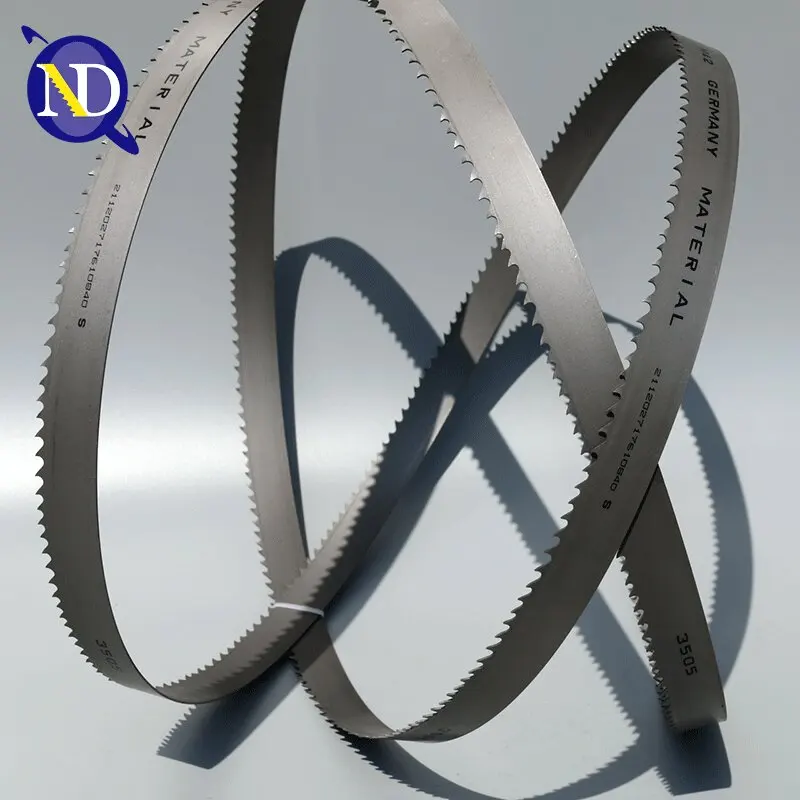

The blade size and shape you need is next. The band saw blades differ from others in their width. It differs also by the shape of the blade and the pattern on teeth. Some have teeth to better make a certain type of cut, such as curves or straight lines. Knowing what sorts of cuts you plan to make can help guide your blade choice.

The last thing you will notice about the blade you wish to buy. You might be tempted because cheaper blades look like a good deal. But inexpensive blades are frequently constructed of less durable materials. So they can start to break down relatively quickly and can lose their effectiveness. A subpar or bad blade can also pose safety issues. For your safety and the quality of your job, choosing a high-quality blade is must.

TA Wiens Stainless Steel Construction Band Saw28, high-quality construction stainless steel Band saw blade engages in production of high-quality materials band saw sheet metal processing tools, stainless steel band saw blade drawn and cold drawn reduces Sag astronomical adviser. It delivers clean cuts and is long lasting, so it’s ideal for serious projects.

Bi-Metal Blades - A special blend of high-speed steel and a tough, flexible backing material. This unique combination allows them to cut through hard materials such as stainless steel, making them one of the best and most advanced solutions. You can do a lot of different cutting jobs with them and they are made for the long haul.

Tooth Count - Different tooth counts are appropriate for various stainless steel thicknesses. So for example a blade with less teeth is better Yanged for cutting thicker pieces. On the other hand, a dull saw is more suited for cutting thinner slices. Knowing this will allow you to make smoother cuts.

Copyright © Kunshan Jenada Machinery Co.,Ltd. All Rights Reserved - Privacy Policy