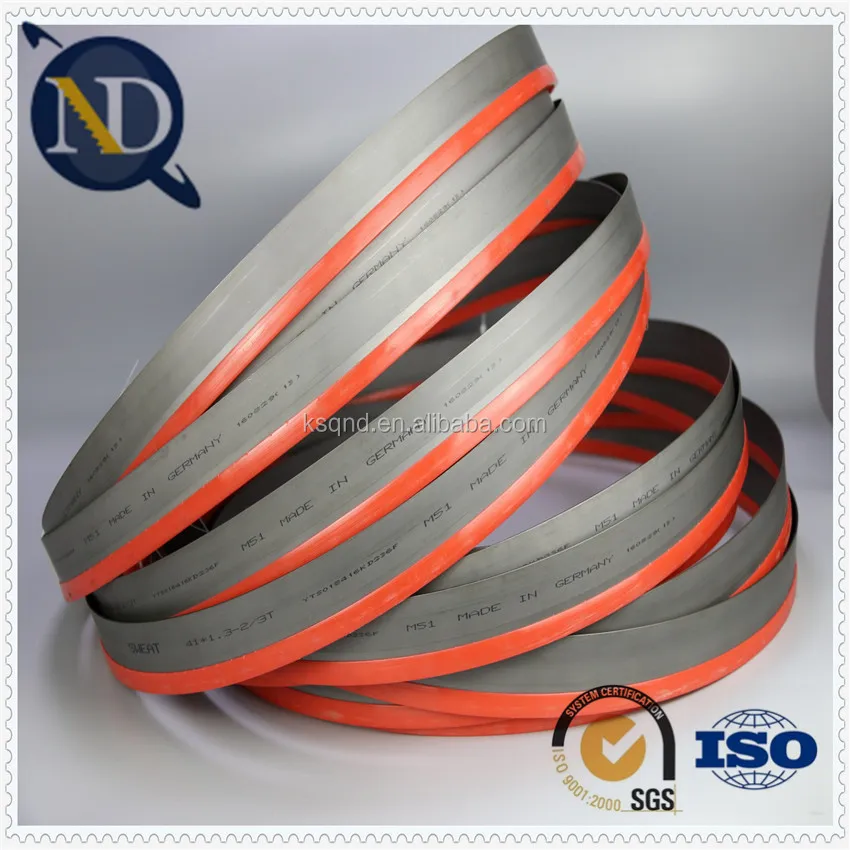

If you don’t use the right tools for the job, cutting stainless steel tubing can be tricky and challenging. It can be really frustrating if things aren’t going as you expected. But don’t worry! With the correct band saw blade in hand, cutting stainless steel tubing may feel like a walk in the park. SWEAT is a leading company that produces high-quality band saw blades for your cutting needs. The right tools make you feel more secure in your trade!

There are some key consideration when choosing a band saw blade for stainless steel tubing projects. First, you want to check something called tooth pitch. This term indicates how many teeth are present on the blade per inch. Tooth pitch is incredibly critical since it determines the speed and efficiency to which the blade will cut. For stainless steel tube cutting, 18 or 24 pitch is the preferable blade choice. These options provide a balance of both speed and precision.

You also have to think about the blade width. Width: This is how thick the blade is. For tubing less than two inches wide use a 3/8-inch wide blade for clean cuts. But if the tubing is greater than two inches wide, then a 1/2 inch-wide blade may be more appropriate for your application. You need to select the width of the blade according to the size of the tubing so that you can cut it effectively.

Lastly, consider the material and thickness of the tubing you are cutting. For optimal results, various blades may be needed for different materials and thicknesses. In general, tubes with fast cutting speeds and higher number of teeth per inch are more suitable for cutting thin-walled tube. Conversely, thicker-walled tubing often requires a blade with fewer teeth per inch and a slower cutting speed. Having these details can allow you to select the right blade.

14 TPI Carbide Tipped Band Saw Blade — This blade has 14 teeth per inch and is a great option for cutting stainless steel tubing up to 2 inches in diameter. The teeth are carbide tipped, making the blade incredibly tough and accurate—helping you to make confident cuts.

To enable you to work at optimal efficiency, you should select a blade with a tooth pitch that matches the diameter of the tubing that you are cutting. The correct blade width also prevents the blade from wandering or moving around in cut, so you will use this to work faster and more efficiently.

When cutting it is important to be precise as well. You get much higher precision by choosing a blade according to the finishing you want to achieve on the tube. Blades with fewer teeth per inch (TPI) produce a coarser finish than those with more TPI, which tend to smooth it out. Lastly, the ideal blade also breaks-down burrs and minimizes welding distortion, making sure it does best and most accurate lines.

Copyright © Kunshan Jenada Machinery Co.,Ltd. All Rights Reserved - Privacy Policy