Have you ever tried cutting a piece of metal with a saw? It can be extremely difficult, and sometimes a certain type of blade will be exactly what you need to do the work properly. In this guide, we will cover everything you need to know regarding the best bandsaw blades for cutting aluminum. We’ll cover the types of all blades, how to decide which to pick for your project, and some specific examples.

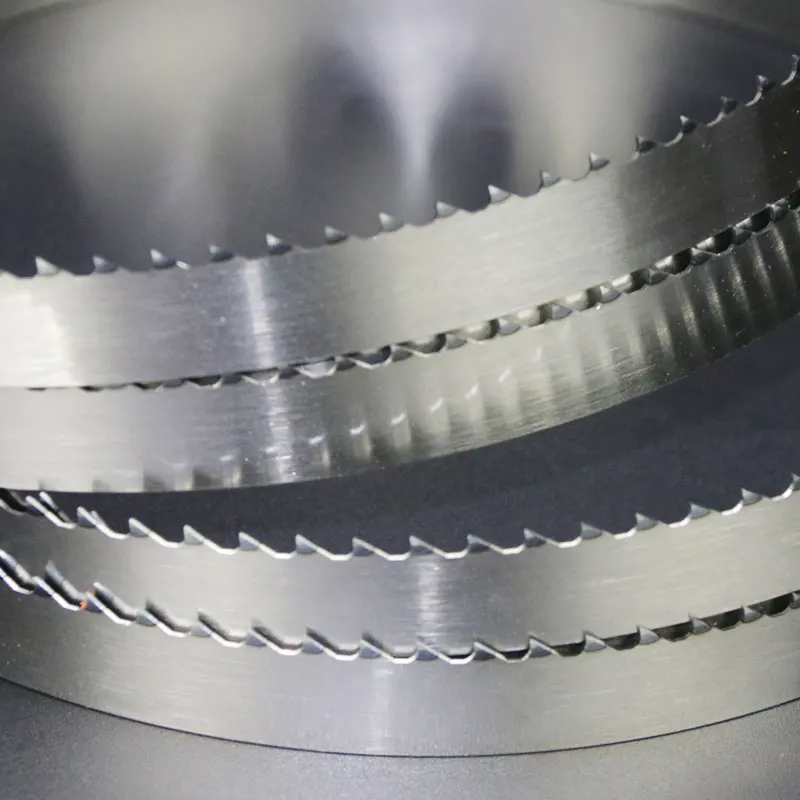

The bi-metal blades are composed of two distinct varieties of metal. This combination of materials makes them exceptionally sturdy and tough. They easily slice through aluminum and do a good job with other materials, including steel and wood. As they last for a long time, there is no need for replacing them frequently.

Another great option for cutting aluminum is a carbide-tipped blade. Its teeth are very hard enough, made with a good equipment, carbide ( an compounded product of carbon and metal which will be very harder than steel). These blades have hard teeth with small pointed tips, which allow them to cut through tough materials such as aluminum without quickly dulling. This can be used for many projects and replace it each time, but rather can be used for a long period of time.

High-speed steel blades work well when cutting through thinner sheets of aluminum. These blades are made from a steel that has the capability of withstanding high temperatures. Which is why they are ideal for cutting metal without being dulled. Using these blades will give you a clean cut if you have to work on something that needs precision and care.

A solid alternate is the carbide-tipped SWEAT bandsaw blade. This carbide-tooth blade is designed for cutting tougher materials (such as aluminum). And it’s also extremely durable, so it’s going to last a long time before you have to replace it. If you are looking for a nice blade that will serve you well in your projects this is a nice option.

Tooth Pattern — The tooth pattern of the blade is also an important part of its functionality. Blades with a high tooth count are preferred for cutting thinner materials, while blades with a low tooth count are preferable for thicker materials. Be sure to select the appropriate pattern depending on what you're cutting.

The material of the blade matters. As previously stated, bi-metal blades are excellent for their robustness, whilst carbide-tipped blades are excellent for slicing through difficult materials like aluminum. How and what you need to know about the materials will help you choose the best alternative for your project.

Copyright © Kunshan Jenada Machinery Co.,Ltd. All Rights Reserved - Privacy Policy