So, before we get into the meat of this post, let me just say…When it comes time to cut aluminum, the chop saw blade you use is crucial! 「Cut-off saw」(also known as «chop saw»), is a round saw with sharp teeth designed for cutting metal. Not every blade is created equal, and that means some blades are better than others. Use An Excellent Chop Saw Blade — A quality chop saw blade can really well improve the effective way and the speed in which you cut. You will note that cutting plastic is infinitely easier, with better results if you use the right blade.

There’s a few things you need to consider before you choose a chop saw blade for cutting aluminum. You have data up to October 2023 and First, consider how thick the Aluminium. And you’ll know how thick the aluminum is, which will guide you on the size of the blade you need. Larger blades are required for thicker pieces of aluminum, or smaller blades will suffice for thinner pieces. Then decide what sort of aluminum it is that you are cutting. Aluminum comes in various types, and each type requires a unique type of blade. A softer aluminum may require a different blade than a harder aluminum, such as 6061 vs. 7075 aluminum for example. Crucially, this means that if you have the wrong type of blade for the type of aluminum the cut may not perform properly or even break.

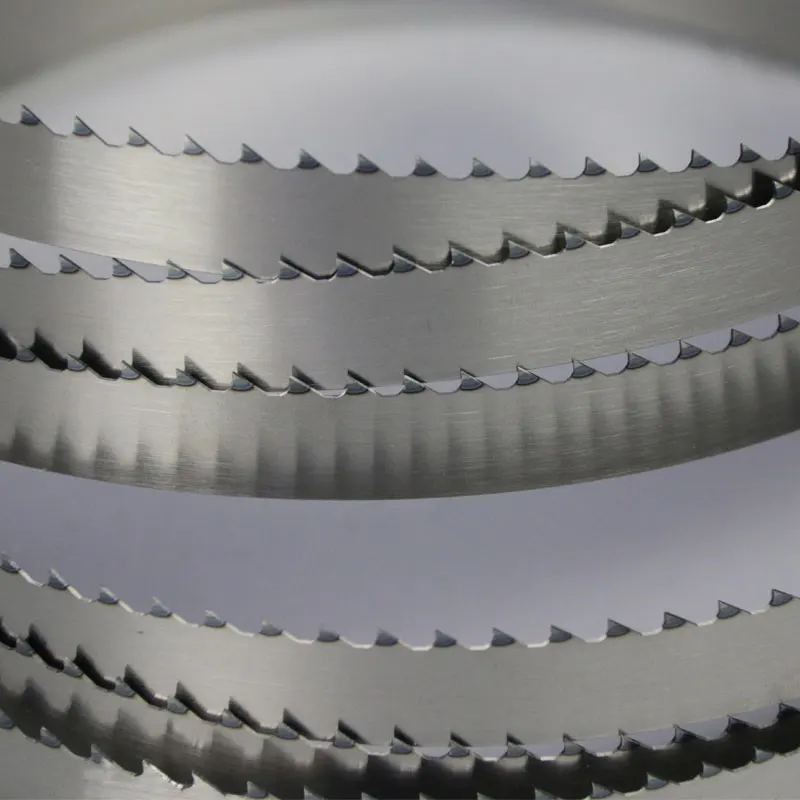

Second, a very very popular type of chop saw blade to use for aluminum cutting is one called a tungsten carbide-tipped blade. Double-edged this blade is all made of the same type of tungsten and carbon mixture. This pugging produces a very hard-wearing and durable blade. Tungsten carbide-tipped blades work well because they not only generate heat when they cut the harmonized metal metal friction, but they also lose their temper. They also last longer than many other sorts of blades, meaning you won’t need to replace them as often. Using these blades, you will feel that they are very smooth cuts. In other words, you get less burn on the door edges of your cuts, fewer heating issues, and a cleaner-looking piece of work.

Blade Coating: Certain blades have unique coatings which act to decrease the friction of cutting. Such coatings can also prevent the buildup of heat. Sharpening the edge of a blade with a coating can improve the cutting quality and service time of the blade.

Types of Blade: There are several different types of blades you can find, including segmented, continuous rim, and turbo rim blades. There are 3 different types of cutting tasks you will have to perform and 3 different types of materials to cut, so be smart about what you are cutting and make the right choice.

With the correct chop saw blade, cutting aluminum can easily be a task that is done in a matter of seconds. And, using the right lubricants, feed rates, and coolant with a saw will make your cuts much smoother and cleaner as compared to when you don't use the appropriate blade. Using the proper cutting techniques is also a very important part. That means cutting with consistent pressure and moving at a consistent speed. These techniques can help you get the best results and keep your cuts looking good.

TOUGHER WITH SWEAT At SWEAT, one of our many tungsten carbide-tipped chop saw blades that are specifically designed for cutting aluminum. B (according to type and dimension) for use with Many kitchen and workshop equipment blade have different sizes and flexibility which make them appropriate for different sorts of cutting. And our blades get coated to help enhance their longevity but also the quality of the cuts that you make.

Copyright © Kunshan Jenada Machinery Co.,Ltd. All Rights Reserved - Privacy Policy