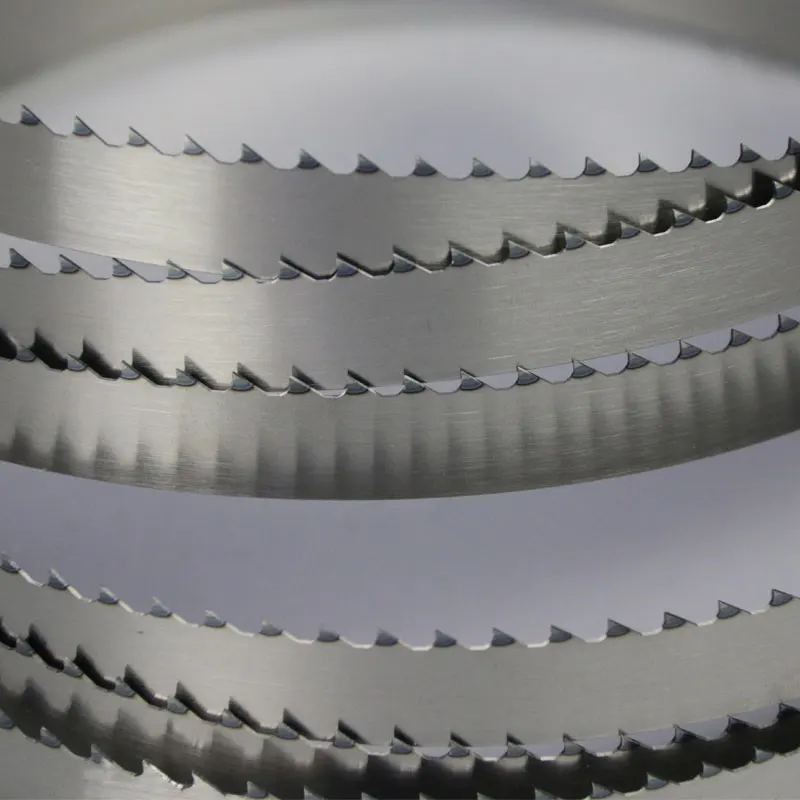

Kahdenmetalliset ketjusahkopisat ovat leikkausalusteita, jotka on suunniteltu erityisesti metallisoihin sovelluksiin. Nämä pisat ovat ainutlaatuisia siinä, että ne koostuvat kahdesta eri metallitasosta. Tämän ansiosta ne ovat samanaikaisesti vahvoja ja joustavia. Kaikki tämä tarkoittaa, että ne voivat leikata läpi monenlaisia muotoja ja metalleja suhteellisen helposti. Tämä tekee niistä niin suosittuja monissa teollisuudenaloissa.

Kahdenmetallisten ketjusahkopisien teollisuus on pieni, mutta erittäin keskeinen osa työkalujen valmistusmaailmassa. Ne käytetään leikkaamaan erilaisia metalleja, kuten teräs-, alumiini- ja kuparipuitteita. Kahdenmetalliset ketjusahkopisat käytetään monella yrityksellä ja teollisuudenalalla. Esimerkiksi rautaa käyttävät yritykset käyttävät näitä pisoja, mukaan lukien autonvalmistajat, rakennuskohdat ja metalliteollisuuden yritykset. Kahdenmetalliset pisat koostuvat kahdesta eri metallista, jotka on liitetty yhteen, mikä mahdollistaa paremman suorituskyvyn verrattuna tavalliseen ketjusahkopisaan.

Bi-metallisten ketjusaavien tuotanto tunnetaan nimellä lasaaminen. Tämä on keskeinen askel, joka vaikuttaa vahvaan ja kestävään saaviin. Ensimmäiseksi työntekijät ottavat kaksi metallilevyä: toinen on kova ja toinen pehmeä. Sitten nämä kaksi levyä lämmitettävät erittäin korkeaan lämpöön. Kun ne ovat lämmittyneet, niitä painostetaan voimakkaasti yhteen compressioon. Tämä antaa vahvan suunnatun ominaisuuden kahdelle kerrokselle, jotka liitetään yhteen, mikä johtaa saaviin, joka säilyttää parhaat ominaisuudet sekä kovasta että pehmeästä metallista. Näin saat kestävän, laadukkaan saavimerkin, joka pystyy käsittelemään vaikeita tehtäviä.

Kahdenmetalliset ketjusahat tarjoavat runsaasti etuja, mikä tekee niistä monien yritysten suosituimman valinnan. Yksi merkittävimmistä eduista on niiden kyky selvitä helposti eri metallityyppien läpi. Ne ovat myös kestaviempitä verrattuna muihin sähkökettujen tyyppiin. Pitkällä tähtäimellä se tarkoittaa, että yritykset eivät tarvitse korvata niitä yhtä usein. Lopuksi, kahdenmetallisten ketjusahien huolto ja ylläpito vaativat vähemmän vertailtuna muihin sähkökettuihin. Tämä on suuri etu aikakriittisissä teollisuudenaloissa. VINKKI: Niiden alustava hinta saattaa olla korkeampi kuin muiden tyyppien sähkökettujen, mutta pidempi elinajan myötä ne ovat taloudellisemmat pitkällä tähtäimellä.

Bi-Metal-kaatovärin veistinkaluston paljous on muuttunut "terveeksi" liiketoiminnaksi yli kahdenkymmenen vuoden kasvun myötä; bi-metalliveistinten kysyntä on täyttämätön. Lopputuotteen valmistus on monimutkainen prosessi, johon vaaditaan taitavaa työvoimaa kentän kokemuksesta. Jokainen veistin on tehty tarkkojen määrittelyjen mukaan niin, että ne toimivat oikein. Yhdysvalloissa sijaitseva Sweat on teollisuuden johtaja bi-metallikaatovärin veistinkaluston tuonnossa ja laatu on tulosta merkille brändille. Heidän koneensa ovat huipputasoisia ja heidän työntekijönsä kuuluvat teollisuudessa korkeiten koulutetuista.

Viime vuosina kysyntä yhä enemmän bi-metallibändisauvoja kasvaa, markkinoiden kysyntä kasvaa ja on olemassa vaurasta kehitystrendiä, ja enemmän valmistajia tarvitaan täyttämäänksesi markkinoille annettu vastaus. Useammat teollisuuden alat hyödyntävät näitä sauvoja yhdessä useamman valmistajan kanssa, jotka tuottavat niitä sen takia, että tällaisista tuotteista on kysyntää. Sweat on johtanut tätä laajentumista toimittamalla korkeakokoisten bi-metallibändisauvoja maailmanlaajuisesti yrityksille. Sweat tunnetaan parhaiten innovaatiostaan ja kyvystään pitää korkeat standardinsa, mikä varmistaa, että se pysyy edelläkävänä bi-metallibändisauvon valmistusteollisuudessa vuosikymmenin ajan.

Tekijänoikeus © Kunshan Jenada Machinery Co.,Ltd. Kaikki oikeudet pidätetään - Tietosuojakäytäntö