Materiale: Forskjellige er laget av ulike materialer, som diamant, karbid og stål. Det finnes forskjellige spesielle egenskaper ved hvert materiale. For eksempel er karbidblader varige og drar bedre gjennom tykkere glass; derfor er de egnet for tungere arbeid. Diamantblader, til motsetning, er virkelig skarpe, og de gir best ytelse ved å kutte mønstre som er veldig små og intrikate. Kort sagt, hvis de trenger nøyaktige snitte, kan diamantbladet være den optimale løsningen for dem!

(Oct03,1,0,0,0)Størrelse: Klingene endrer mye i størrelse. Noen klinger er små og ideelle for nøyaktig skjæring, mens andre er lange og egnet for store prosjekter. Med klingen, tenk på prosjektet du har i tankene. En mindre kling vil hjelpe deg med å skjære mindre former hvis du trenger det. En lengre kling vil være nyttig i større prosjekter.

Kostnad: kostnaden for glassskjæringsblader kan variere mye. Mens høyere kvalitet blader kommer til en større pris, er de også mer varige. Derfor har de en lengre levetid og er mer effektive for dine skjæringskrav. Hvor mye du ønsker å bruke avhenger av hvilket blad du velger. Noen ganger å betale litt mer vil føre til besparelser over tid, siden du ikke må bytte ut bladet så ofte.

Bruk trykk: Mens du skjærer glaset, hold et konstant trykk på glasset. Det betyr at du bør trykke ned i stedet for å skubbe mens du skjærer. Sett for lite trykk, og det kan sprække eller bli ødelagt. Derfor bør du holde et ganske jevnt trykk for å kompensere for små feil hvis de skulle oppstå.

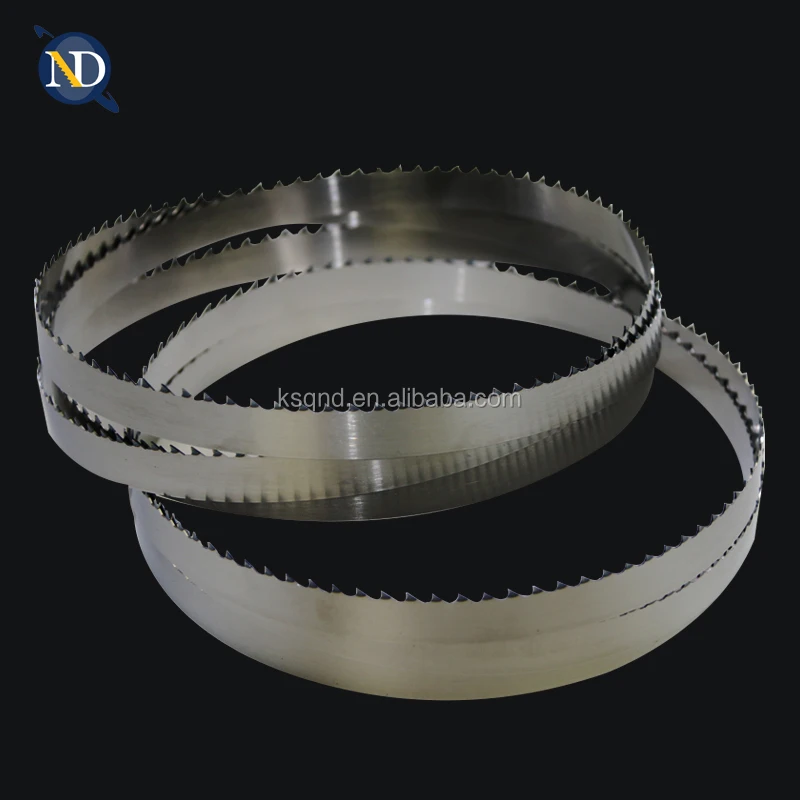

Bladekant: Delen av bladen som er skarp og kommer i kontakt med glasset. Denne skjæringskanten består vanligvis av veldig hårde materialer som stål eller karbid, hvor diamant er den hardeste. En enda skarpare kant vil gjøre det enklere å skjære gjennom glasset.

Kerf: Kerf er den lille mellomrommet som skjæringen lar etter seg når du skiller glasset. Mer om dette mellomrommet (vanligvis omtrent 1mm bredt) senere. Å forstå kerf-et er nyttig fordi det vil påvirke hvordan delene dine passer sammen godt hvis du lager noe som krever en perfekt passform.

Rengjør det hver gang: Hver gang du bruker bladet, sørg for å rengjøre det godt – med en myk klut og litt rubbing alcohol. Dette hjelper til å fjerne skitt og avfall som kan ha akkumulert. Rengjør ditt blad, og det vil fungere bedre og vare lenger hvis du holder det rent.

Opphavsrett © Kunshan Jenada Machinery Co.,Ltd. Alle rettigheter forbeholdes - Personvernpolicy