Material: Skilda är tillverkade av olika material som diamant, karbid och stål. Varje materials har sina egna speciella egenskaper. Till exempel, karbidbladen är beständiga och tränger djupare in i glas; därmed är de lämpliga för tyngre arbete. Diamantbladen, å andra sidan, är mycket skarpa och presterar bäst när de skär små och komplexa mönster. Kort sagt, om de behöver precisa skärmärken, kan diamantbladet vara den optimala lösningen för dem!

(Oct03,1,0,0,0)Storlek: Bladen ändras mycket i storlek. Några blad är små och idealiska för precist skärning, medan andra är långa och lämpliga för större projekt. Tänk på vilket projekt du har i tankarna när du väljer blad. Ett mindre blad kan hjälpa dig att skära mindre former om du behöver det. Ett längre blad kommer att vara till nytta i större projekt.

Kostnad: kostnaden för glas skärblad kan variera mycket. Medan högkvalitativa blad kostar mer, tenderar de också att vara mer hållbara. Därför har de en längre livslängd och är mer effektiva för dina skärbehov. Hur mycket du vill spendera beror på vilket blad du väljer. Ibland betalar du lite mer, men sparar pengar med tiden, eftersom du inte behöver byta ut bladet lika ofta.

Använd tryck: Medan du skär glaset, håll ett konstant tryck på glaset. Det betyder att du ska trycka ner istället för att skjuta ner när du skär. Om du sätter för lite tryck kan det spricka eller brytas. Därför behåller du ganska jämnt tryck för att kompensera för en liten olyckshändelse om den skulle inträffa.

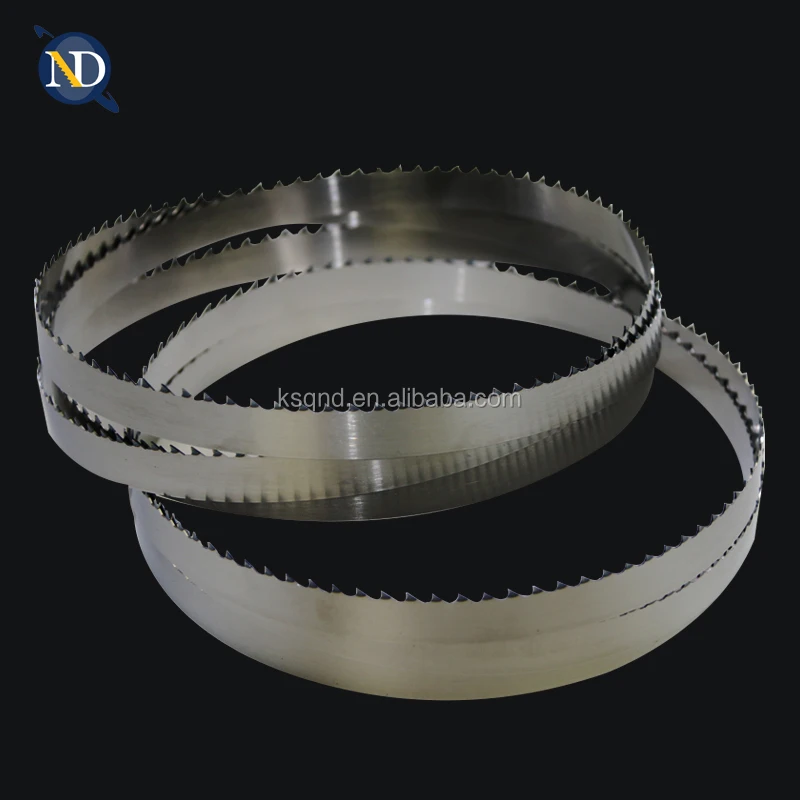

Knivkant: Delen av bladet som är skarp och kommer i kontakt med glaset. Denna skärkant består vanligtvis av mycket hårda material som stål eller karbid, diamant är det hårdaste. En ännu skarpare kant gör det enklare att skära genom glaset.

Kerf: Kerf är den lilla mellanrummet som skärningen lämnar efter sig när du separerar glaset. Mer om detta mellanrum (vanligtvis cirka 1 mm bredt) senare. Att förstå kerf är användbart eftersom det påverkar hur dina delar passar ihop bra om du gör något som kräver perfekt anpassning.

Rensa det varje gång: Varje gång du använder bladet, se till att rensa det ordentligt - med en mjuk duk och lite alkohol. Detta hjälper till att ta bort smuts och skrot som kan ha ackumulerats. Rensa ditt blad, och det kommer att fungera bättre och hålla längre om du håller det rent.

Copyright © Kunshan Jenada Machinery Co.,Ltd. All Rights Reserved - Integritetspolicy