lưỡi cưa băng kim loại hai lớp là một trong những công cụ rất quan trọng của nó. Dù …">

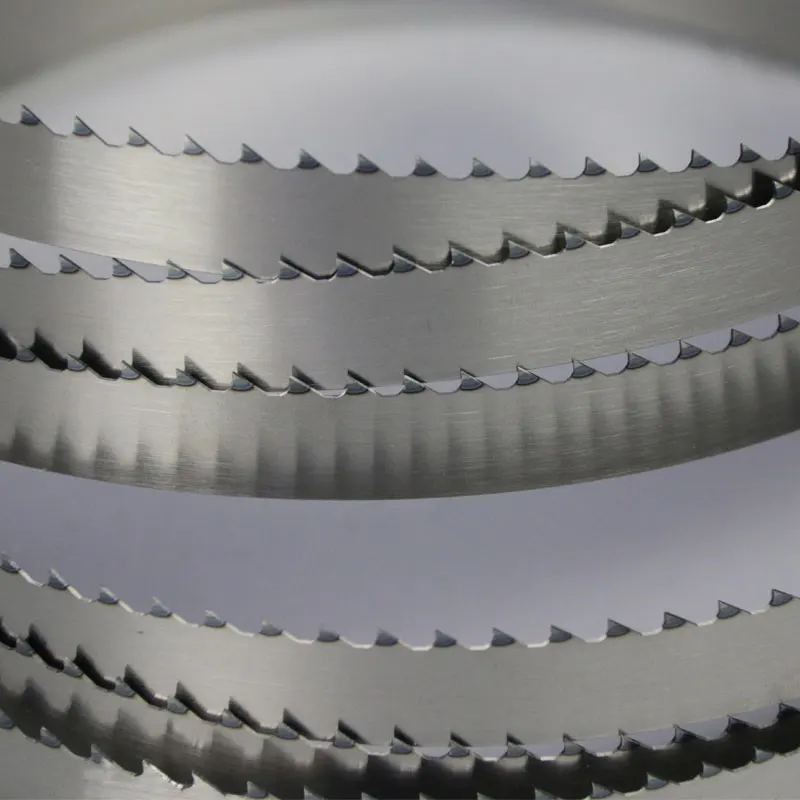

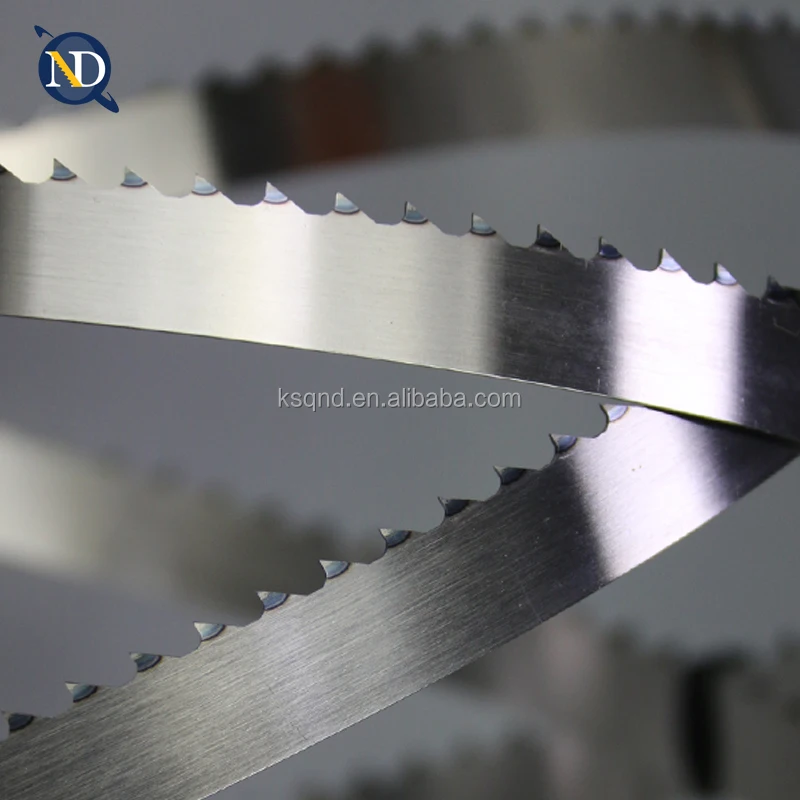

Chào mọi người! [Top 10] Lưỡi Dao Cưa Băng Để Thảo Luận Hôm Nay Vì cưa băng được sử dụng để cắt các vật liệu khác nhau, lưỡi cưa dây kim loại phức hợp là công cụ rất quan trọng của nó. Dù bạn đang cắt gỗ, kim loại hay thậm chí là nhựa, việc sử dụng lưỡi cưa băng phù hợp cho dự án của mình có thể tạo ra sự khác biệt lớn. Tại SWEAT, chúng tôi muốn giúp bạn chọn lưỡi cưa tối ưu cho công việc của mình và duy trì khả năng hoạt động trong thời gian dài.

Bạn có thể làm được nhiều việc với một cưa đai, nhưng trước tiên bạn cần học cách tại sao nên chọn lưỡi cưa đai phù hợp cho công việc hiện tại. Có nhiều loại lưỡi, mỗi loại được thiết kế cho các vật liệu cụ thể. Nếu bạn muốn cắt theo đường cong và các đường không thẳng, bạn sẽ cần một lưỡi cưa hẹp với nhiều răng để thực hiện công việc này. Loại lưỡi này sẽ cho phép bạn thực hiện cả những đường cắt mượt mà và chi tiết. Tuy nhiên, một lưỡi cưa rộng hơn với ít răng hơn là lựa chọn phù hợp khi cắt qua những miếng gỗ hoặc kim loại dày. Nó có thể cắt vật liệu tốt hơn và giúp công việc của bạn dễ dàng hơn.

Việc sử dụng lưỡi cưa phù hợp sẽ đảm bảo rằng bạn có những đường cắt nhanh hơn với độ chính xác cao hơn. Điều này có thể gây phiền phức và thậm chí làm hỏng công cụ của bạn. Một lưỡi cưa bị tù hoặc gãy cũng rất nguy hiểm khi sử dụng. Việc chọn lưỡi cưa phù hợp cho công việc hiện tại là vô cùng quan trọng để tránh các sự cố và đảm bảo những đường cắt chính xác, sạch sẽ.

Một cách để giữ cho máy của bạn hoạt động tốt nhất là giữ lưỡi cưa chặt, để nó không rung lắc trong khi cắt. Bạn cần đảm bảo rằng nó được căn chỉnh đúng cách. Ma sát được giảm thiểu bằng cách sử dụng chất bôi trơn đặc biệt cho lưỡi cưa, giúp lưỡi cưa di chuyển dễ dàng khi cắt. Khi bạn đã hoàn thành công việc với cưa lọng, luôn là một thói quen tốt để lau sạch tất cả sawdust và bụi bẩn thường tích tụ. Điều này giúp giữ lưỡi cưa của bạn ở trạng thái tốt và sẵn sàng cho công việc tiếp theo của bạn.

Lưỡi dao thép tốc độ cao có thể được sử dụng cho nhiều công việc cắt gỗ và kim loại khác nhau. Chúng thường rẻ hơn, nhưng chúng nhanh bị cùn, đặc biệt khi cắt các vật liệu cứng hơn. Lưỡi dao có đầu bằng cacbua có tuổi thọ lâu hơn nhiều, cho phép cắt qua các vật liệu cứng mà không bị cùn quá nhanh. Các lưỡi dao này thường đắt hơn so với lưỡi dao thép tốc độ cao. Lưỡi dao song kim đại diện cho sự折trung gian giữa hai loại trên. Chúng cứng như lưỡi dao cacbua nhưng cũng linh hoạt như lưỡi dao thép tốc độ cao, đó là lý do tại sao chúng phổ biến trong các nhiệm vụ cắt công nghiệp.

Một chỉ số TPI cao hơn đối với một lưỡi dao cụ thể cho thấy khoảng cách răng nhỏ hơn, điều này giúp đảm bảo một đường cắt mịn hơn. Ngược lại, ít răng hơn sẽ tạo ra đường cắt thô hơn. Một ví dụ điển hình về TPI là lưỡi dao 6 TPI thích hợp nhất để cắt nhanh qua các miếng gỗ dày, trong khi lưỡi dao 24 TPI phù hợp hơn cho công việc chi tiết hơn và tạo ra bề mặt hoàn thiện mịn màng.

Cuối cùng, chúng ta cần xem xét đến vấn đề an toàn khi sử dụng một lưỡi cưa đai bimetal . Nếu không được xử lý đúng cách, những lưỡi dao này có thể cực kỳ nguy hiểm. Như thường lệ, hãy đeo kính bảo hộ khi làm việc với công cụ của bạn. Các hình ảnh này đã được phóng đại bằng ống nhòm. Như vậy, nó có thể bảo vệ mắt bạn khỏi các mảnh văng ra. Trong khi cắt, cũng rất quan trọng là giữ ngón tay và các bộ phận khác của cơ thể ở khoảng cách an toàn từ lưỡi dao.

Bản quyền © Công ty TNHH Máy móc Kunshan Jenada. Mọi quyền được bảo lưu. - Chính sách bảo mật