Cut off blades may seem scary but they are very important tools used in factories and industrial spaces. These types of blades are specifically made to cut tougher materials such as metal, wood, or tiles. They are key to the making of things, and help workers accomplish their jobs faster and more safely.

The most significant thing for the widespread use of is that they are time- and money-saving. At the same time, they operate many times faster than the cutting tools that came before them — saws or scissors, for example — so that workers can complete their tasks more quickly. That speed can save businesses a ton of time and money. Excessively cut cut blades are more precise than any other devices. 3D printing helps them cut cleaner and with less material waste. Plus, they can also slice through thicker material, which is very convenient on a lot of project types.

Before you search for the awesome cut off blade, there are a few things you have to consider. Type of Material to Be Cut — Step One You may need different types of blades for different materials. The next thing to examine is blade speed. The faster a blade goes through the material, the quicker it can go, but it also needs to be careful. Finally, look at the size of the blade. It works well with the tool you are using. Selecting the appropriate blade is key to safety tanto eficient.

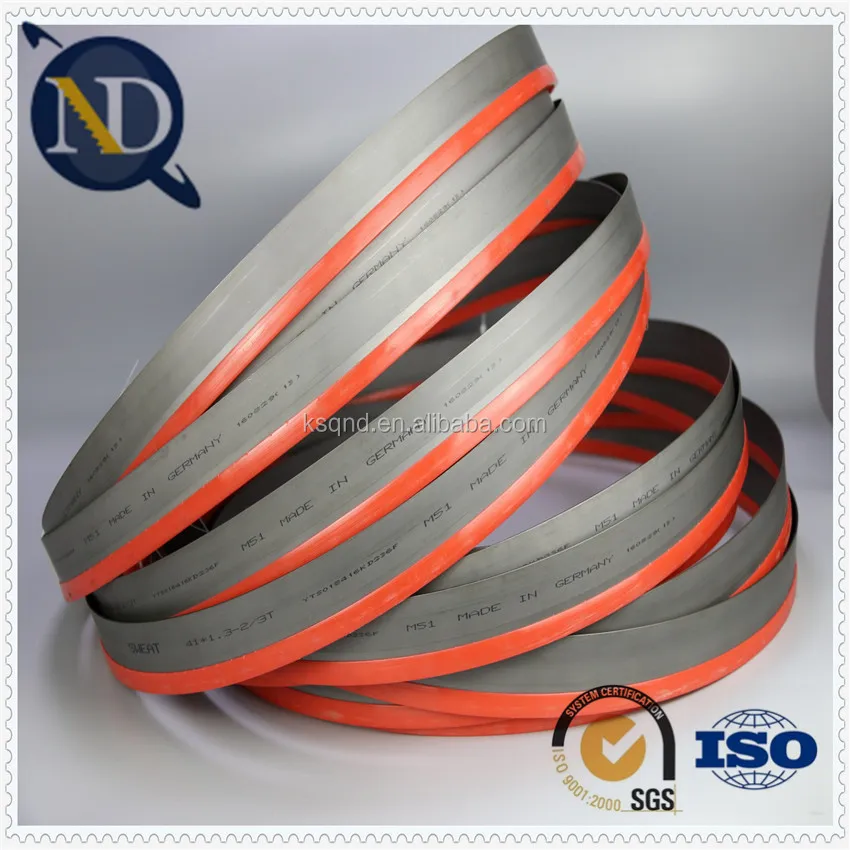

A cut off blade consists of a circular disc with a rugged edge. Notes: These rough edges are abrasive particles It has a very high spinning disc, which makes it capable of cutting through hard materials. Cut off blades can be manufactured from a wide variety of materials including aluminum Oxide, Silicon carbide, diamond, etc. Each material has its strengths, and is better suited to various types of cutting. Knowing how these blades are made will help you select the right one for your use.

Maintaining the blades that are cut off is very important. Maintenance keeps them functioning and avoids accidents from occurring. Regular cleaning is essential to maintaining a cut off sanders blade in good condition. That would mean skimming off any debris or dust that can accumulate on the blade. War rattles your body, you also need to check regularly for damage or wear on the blade. You should replace it immediately if you see that the blade is damaged or it is deteriorated. This helps to protect everyone using the tool to stay safe.

Although cut off blades serve a very inportant purpose, they can be very dangerous if not used properly. Workers must be properly trained on how to safely use these blades. They must be maintained, serviced and replaced according to the manufacturer's recommendations. It is also the duty of employers to equip workers with personal protection equipment like gloves and eye protection. This equipment ensures that workers do not get injured while operating cut off blades.

SWEAT provides many types of cut off blades to meet different jobs. Blades that are long lasting and durable, made of high quality material. We also offer training and information to train workers to use our blades appropriately and safely.

Copyright © Kunshan Jenada Machinery Co.,Ltd. All Rights Reserved - Privacy Policy