There are several important factors in cutting various materials that determine its success or failure. We get you need the right tools of the trade to do your best. Bandsaw blades are available in a plethora of patterns, with each pattern is evolved for particular materials. Whether you’re working with metal, wood or plastic, the perfect tooth design lets you achieve smooth cuts and finish your project in less time. Different materials call for different methods and the right blade can save you time and energy. First, we will talk about selecting the best bandsaw blade for metal fabrication and then we will tackle how to cut plastics.

How to Select the Best Bandsaw Blade for Metal Fabrication?

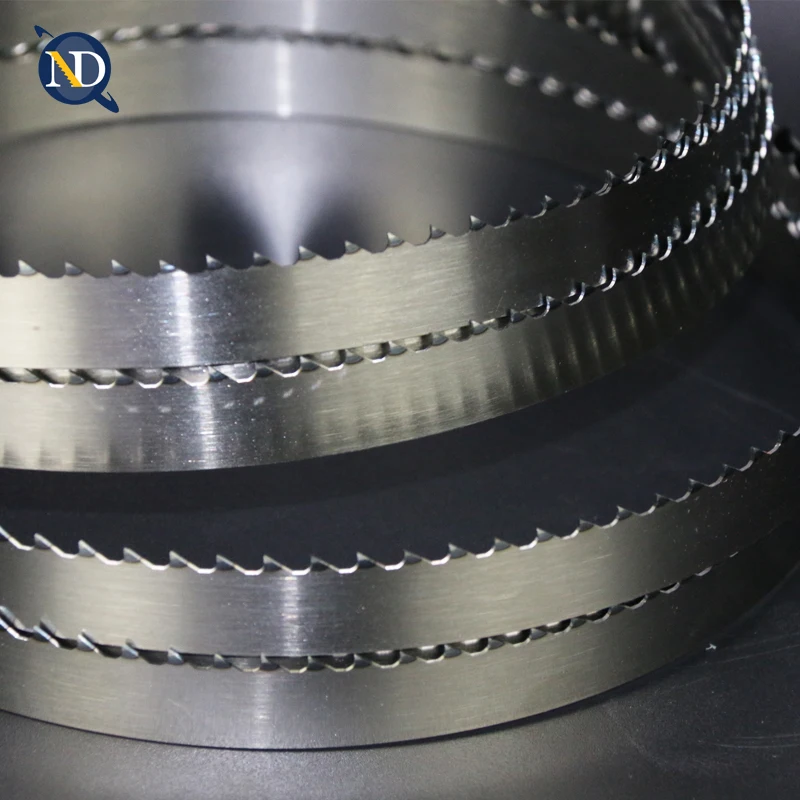

You need a blade that can take whatever you throw at it when cutting through metal. HSS (high-speed steel) blades are generally the most suitable for metalwork fabrication. HSS blades are generally sharper and can cut many materials, including aluminum and steel. The teeth on these blades also matter. For metals, fewer teeth per inch (TPI) is generally better. This is because a low TPI count clears chips and debris while cutting, so the blade doesn't get stuck. For instance, if you’re cutting thick steel, a blade with 3 to 4 TPI is ideal. But if you’re slicing through thinner metals, like metal sheeting, you might prefer a blade with 10 to 14 TPI.

Tooth design is another thing to consider. Most blades are hook tooth, which is a forward angle on the teeth. This is beneficial to cutting quicker which is awesome for production work. But if you require more accuracy, a straight-toothed blade might be best. It’s a slower cutter and has a smoother finish. And also don’t forget to measure the blade width. Wider blades work well for straight cuts, but can be more difficult to manage when following curves. So, in choosing, consider the kind of metal, thickness of material and type of cuts you need to make. SWEAT provides several cutting blade selections to accommodate these needs effectively.

How to Choose the Right Blade for Cutting Plastics

Plastics behave differently than metal when you cut into them. For plastics the solution is usually to have a fine-toothed blade. A blade with somewhere between 14 and 24 TPI is ideal for making clean cuts that do not melt the plastic. This is really important because the blade has a tendency to get super hot and melt through the plastics. A blade that is for plastics is usually a special type of tooth design. The teeth of these blades frequently is flat- topped which ensures smooth flowing cutting operations.

A thinner blade may be practical for cutting softer plastics (like PVC or acrylic). It reduces the chance of cracking or chipping edges. Thicker plastics, like polycarbonate, can benefit from a wider blade to keep the cuts nice and straight. Low speed is also good, it allows you more control and can help prevent melting. A slow feed of the teeth helps the cutters to avoid excessive heat, and also it makes easier to manage the material. Depending on the different types of plastic you’re working with, it might be useful to have a few blades around. At SWEAT we supply a selection of bandsaw blades specifically developed for cutting at different plastic materials so you get the best results every time.

Handsaws can be a very useful addition to bandsaw when ganged upside, because just common band saws. Whether sawing metal or plastic, a knowledge of tooth design and blade type is the key to good cutting results. Your work piece and the amount of time you spend completing each job will be a factor as well.

What Is The Effect Of Gullet Size On Bandsaw Blades?

The teeth design on the blade is also crucial when cutting with a bandsaw. The tooth pattern may alter how well the blade saws through various materials. As an example, if the teeth are close together, the blade will cut smoother, but perhaps not as fast. If the teeth are too wide apart, on the other hand, your blade will be able to cut more quickly, but the resulting edge may look ragged. The form of the teeth is also important. Some are flat, others pointed and curved. For example, flat teeth are terrific for cutting soft materials such as wood, while pointed teeth perform better on harder materials like metal. When making a selection for a bandsaw blade, consider what you are going to cut. When making crosscuts with thin pieces of wood, a blade that has small teeth spaced close together can help you cut more accurately. If you are slicing thick or stiff metal, a large-tooth blade does better because it can accommodate the material without jamming. Sweat offers several bandsaw blade types, all of which correspond with the various tooth patterns to assist with more efficient cutting. Adjusting for tooth pattern is an easy way to improve performance, which means that understanding the cause and effect of each type will help you select the best blade for your job and increase your productivity.

How Can I Improve Efficiency with the Correct Bandsaw Blade Tooth Design?

Adequate for the task, you will need to select the correct tooth configuration that best suits your project requirements. And efficiency means the ability to cut fast and get clean lines. Material comes into the technology at different directions, requiring varying tooth designs. That can help clear sawdust from a cut. This can prevent the blade from going sideways and then down, making for an easier cut. The SWEAT includes blades with different teeth to fit different materials, so you can find the one for your needs. If you have the correct blade, you'll keep from pushing down hard on the saw. This makes your work simpler, and extends the life of the blade. The blade also must remain sharp. It is easier and faster to cut with a sharp blade. You'll want to have your saw blade checked often for the need of sharpening or a new one. And if cuts aren’t as smooth or take longer, you might be ready for a new blade. You can also improve the speed by changing your bandsaw. With too much speed, the blade can dull rapidly. If you go slower, you only lose time. The best speed to use depends on the material and the design of a blade’s teeth. Knowing these tips can help optimise your work process and 'let the right SWEAT band saw blade make your project easier.

What are Trends of Band Saw Blade for 2023?

Band saw blade technology will change in 2023 designed to help people cut materials better, faster. One large trend is the creation of new materials for the blades themselves. Blades made of good quality steel are in increasing favour, as they prove both more durable and keener. You don’t have to replace your blade as often, which saves you more time and money. Another one is the use of, on purpose designed teeth for processing several type of materials. For instance, some blades now feature alternating tooth patterns that serve to minimize noise and make cutting easier. It is awesome that you can use this design for wood and metal cutting. Another promising trend is the development of green blade technologies. Companies like SWEAT are researching how to make blades better for the environment. That means using recyclable materials and processes that generate less waste. And, finally, technology is creeping into metal bandsaw blades. Some new blades are developed to cooperate with machines that adjust the cutting speed and pressure automatically. So you can have perfect cuts without having to set everything up by hand. Staying current with these trends can be the perfect method for you in selecting the best bandsaw blade. SWEAT designs are cutting edge and you can be rest assured that you are using the latest technology to make your life easier as well!